Where Do We Go From Here?

In this segment, taken from his 2008 talk at the Museum of Modern Art, New York, for his exhibition The Printed Picture, Richard Benson walks us through the the leaps we have taken in photographic printing over its long history. He gives an overview of color calibration and management now possible with the technological capabilities we have today, as well as the digitization of all media, long-edition rotogravure, the indigo printer, the scanner as a camera, and pictures used for machines. Pictures associated with each of the main themes presented in the segment can be found by clicking on any of the fields below.

Where Do We Go From Here? Introduction (19:41 - 22:21)

-

Photo offset lithography. Steve Cannistra. Orion Nebula from Sky and Telescope magazine, May 2004. 2004. 10 1/16 x 6 9/16" (25.6 x 16.6 cm). The Museum of Modern Art, New York. Gift of Richard Benson © Steve Cannistra. The photograph was made by a gifted amateur using digital technology and a small telescope.Photo Offset Lithography

Photo offset lithography. Steve Cannistra. Orion Nebula from Sky and Telescope magazine, May 2004. 2004. 10 1/16 x 6 9/16" (25.6 x 16.6 cm). The Museum of Modern Art, New York. Gift of Richard Benson © Steve Cannistra. The photograph was made by a gifted amateur using digital technology and a small telescope.Photo Offset Lithography

Calibration (00:00 - 02:08)

-

Printer’s color halftone proof. Photographer unknown. Test image created for calibrating a prepress proofing system to a particular offset press. c. 2001. 11 3/8 x 8 1/2" (28.9 x 21.6 cm). The Museum of Modern Art, New York. Gift of Richard Benson. Over the past decade, the capacity of computers to handle ever larger amounts of data has risen sharply. One consequence is that today virtually all offset plates are directly exposed by computer-guided lasers, and stochastic screening methods have replaced the old halftone negatives in silver, eliminating all their complications.This is a test image, used by offset printers to calibrate their scanning, file-tuning, plate-making, and presswork. We must accept the need for such images because virtually all printing done today in ink (and even in photographic labs) is digitally based, and this kind of printing cannot be done properly without careful technical controls. This is the great drawback to the digital revolution in photography and printing—that we must give up the old instinctive, seat-of-the-pants work habits of the traditional darkroom or pressroom and instead be willing to measure and codify visual data to ensure that things turn out the way we envision.This is a terrible thing. Artists have always placed technique on a lesser level than visceral impulse; when they don’t they become craftsmen instead. The line between these two activities is soft and blurry, but the great technical prowess of the finest artists never obscures the fact that their work is valued because their craft carries something far more interesting than the craft itself. A work of art expresses the wisdom of the artist and the craft is the mechanism that brings this wisdom to physical form. This sounds like a bit of a tirade, but I emphasize it because the need to calibrate digital tools and obsessively measure their output is a tremendous obstruction to the artist’s work. Photographers have always faced this problem, because of the mechanical nature of their trade, but in black and white photography the best work has always been done with a minimum of technical complexity. The best photographers have always understood how their medium worked, but seldom was great photography done with gray cards and light meters. Exposures were made based upon experience joining feeling, and only when color-reversal materials came along did as basic a tool as the light meter become necessary. I sometimes even go so far as to say that no great black and white photograph was made with a light meter, unless it was being used to hold up the sagging bellows of an old view camera. This is an extreme point of view, but our test pattern should alert photographers and printers to the great danger lurking in technical controls: that calibration and measurement only have benefits when they connect to established standards, and standards of any sort run absolutely counter to the central tenet of art—that its richest ground is in the field of the unexpected and unpredictable.Printer's Color Halftone Proof

Printer’s color halftone proof. Photographer unknown. Test image created for calibrating a prepress proofing system to a particular offset press. c. 2001. 11 3/8 x 8 1/2" (28.9 x 21.6 cm). The Museum of Modern Art, New York. Gift of Richard Benson. Over the past decade, the capacity of computers to handle ever larger amounts of data has risen sharply. One consequence is that today virtually all offset plates are directly exposed by computer-guided lasers, and stochastic screening methods have replaced the old halftone negatives in silver, eliminating all their complications.This is a test image, used by offset printers to calibrate their scanning, file-tuning, plate-making, and presswork. We must accept the need for such images because virtually all printing done today in ink (and even in photographic labs) is digitally based, and this kind of printing cannot be done properly without careful technical controls. This is the great drawback to the digital revolution in photography and printing—that we must give up the old instinctive, seat-of-the-pants work habits of the traditional darkroom or pressroom and instead be willing to measure and codify visual data to ensure that things turn out the way we envision.This is a terrible thing. Artists have always placed technique on a lesser level than visceral impulse; when they don’t they become craftsmen instead. The line between these two activities is soft and blurry, but the great technical prowess of the finest artists never obscures the fact that their work is valued because their craft carries something far more interesting than the craft itself. A work of art expresses the wisdom of the artist and the craft is the mechanism that brings this wisdom to physical form. This sounds like a bit of a tirade, but I emphasize it because the need to calibrate digital tools and obsessively measure their output is a tremendous obstruction to the artist’s work. Photographers have always faced this problem, because of the mechanical nature of their trade, but in black and white photography the best work has always been done with a minimum of technical complexity. The best photographers have always understood how their medium worked, but seldom was great photography done with gray cards and light meters. Exposures were made based upon experience joining feeling, and only when color-reversal materials came along did as basic a tool as the light meter become necessary. I sometimes even go so far as to say that no great black and white photograph was made with a light meter, unless it was being used to hold up the sagging bellows of an old view camera. This is an extreme point of view, but our test pattern should alert photographers and printers to the great danger lurking in technical controls: that calibration and measurement only have benefits when they connect to established standards, and standards of any sort run absolutely counter to the central tenet of art—that its richest ground is in the field of the unexpected and unpredictable.Printer's Color Halftone Proof

Color Management (02:09 - 03:37)

-

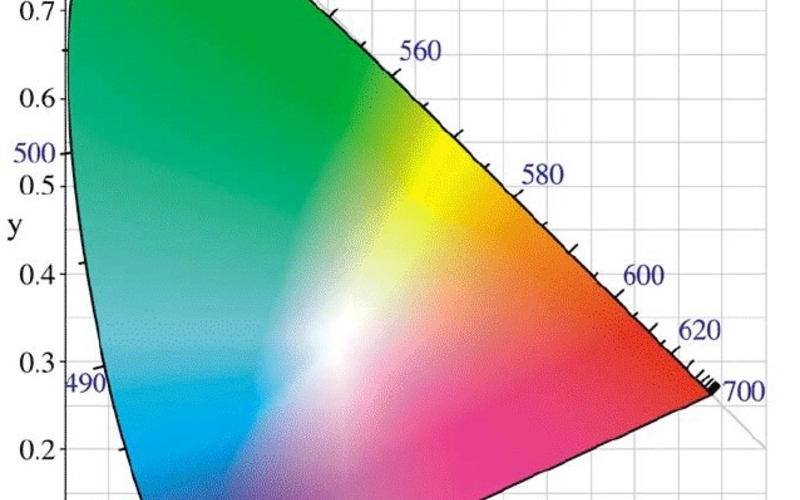

Web download. Commission Internationale L’Éclairage.Chromaticity Diagram. Downloaded 2006. 7 15/16 x 7 1/16" (20.2 x 18 cm). The Museum of Modern Art, New York. Gift of Richard Benson.The issues of calibration have a direct impact on any photographer using the computer because the image on the monitor never looks like the print made from it. The biggest reason for this disconnect is that the monitor image is made in additive color and the print in subtractive color. The monitor literally glows while the passive print simply reflects, and each device uses a different dye set to generate the colors. It is possible to build a hood around the monitor and then make a light box around the print, so that they sit side by side and appear somewhat the same, but this ideal is seldom adhered to, and even when followed, it doesn’t address the fundamentally different colors that the two systems display. Another reason why the monitor image and the print don’t look alike is that every digital device has its flaws: both the scanner doing the input and the printer doing the output introduce errors in the data handling.Also, the monitor, paper, and inks each have their own set of colors, which differ from one another. Technicians say that each stage has its own “color space,” and that there is no hope of making a properly balanced print unless these differences are integrated with each other through some controllable method. What has evolved to do this is a system called “color management,” which uses various “profiles” for each machine and ties the profile data from one device to the next, in a chain of information that in theory will make things turn out right. In a highly controlled laboratory setting these profiles seem to work—sort of. Since the earliest years of their craft, printers have been telling clients that the picture will look right because their methods always work out as planned, but this has never been the case. Color management is based on the premise that all aspects of the process, from scan (or original exposure with a digital camera) to print, can be controlled and that each step along the way will behave as planned. It is possible to use color-management tools to help us make a print, and we can even go to the extreme of buying expensive software to do this, but in the turmoil of technological change (and while trying to follow the instincts of an artist) I have found the system hopeless. If we make photographs and use the new technology to make them, we quickly realize that we are working in an environment similar to that of the automobile in the era of the Model T Ford. We can get great results, but things break down constantly and we have to putter with the machinery. We are a long way away from the time when we can simply turn the key and drive away, secure in the knowledge that we will get where we want to go without unexpected bumps along the way.Web Download

Web download. Commission Internationale L’Éclairage.Chromaticity Diagram. Downloaded 2006. 7 15/16 x 7 1/16" (20.2 x 18 cm). The Museum of Modern Art, New York. Gift of Richard Benson.The issues of calibration have a direct impact on any photographer using the computer because the image on the monitor never looks like the print made from it. The biggest reason for this disconnect is that the monitor image is made in additive color and the print in subtractive color. The monitor literally glows while the passive print simply reflects, and each device uses a different dye set to generate the colors. It is possible to build a hood around the monitor and then make a light box around the print, so that they sit side by side and appear somewhat the same, but this ideal is seldom adhered to, and even when followed, it doesn’t address the fundamentally different colors that the two systems display. Another reason why the monitor image and the print don’t look alike is that every digital device has its flaws: both the scanner doing the input and the printer doing the output introduce errors in the data handling.Also, the monitor, paper, and inks each have their own set of colors, which differ from one another. Technicians say that each stage has its own “color space,” and that there is no hope of making a properly balanced print unless these differences are integrated with each other through some controllable method. What has evolved to do this is a system called “color management,” which uses various “profiles” for each machine and ties the profile data from one device to the next, in a chain of information that in theory will make things turn out right. In a highly controlled laboratory setting these profiles seem to work—sort of. Since the earliest years of their craft, printers have been telling clients that the picture will look right because their methods always work out as planned, but this has never been the case. Color management is based on the premise that all aspects of the process, from scan (or original exposure with a digital camera) to print, can be controlled and that each step along the way will behave as planned. It is possible to use color-management tools to help us make a print, and we can even go to the extreme of buying expensive software to do this, but in the turmoil of technological change (and while trying to follow the instincts of an artist) I have found the system hopeless. If we make photographs and use the new technology to make them, we quickly realize that we are working in an environment similar to that of the automobile in the era of the Model T Ford. We can get great results, but things break down constantly and we have to putter with the machinery. We are a long way away from the time when we can simply turn the key and drive away, secure in the knowledge that we will get where we want to go without unexpected bumps along the way.Web Download

Digital Everything (03:37 - 05:55)

-

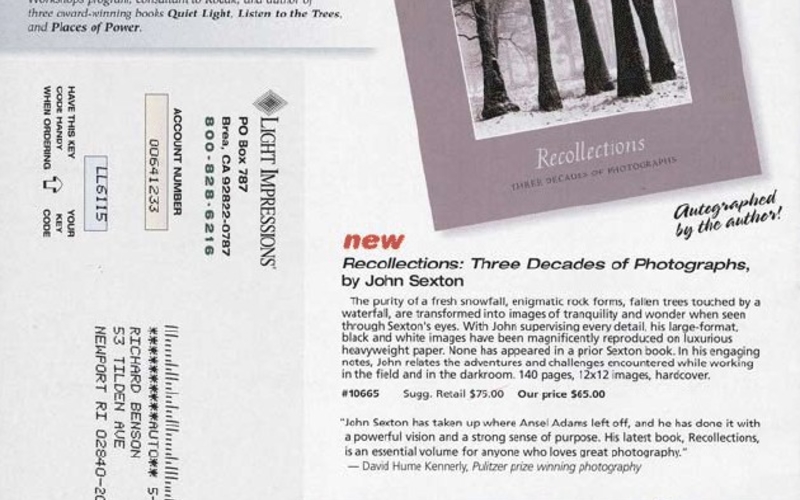

Web photo offset print. Light Impressions Company. Light Impressions mail-order catalog, back cover. 2006. 10 1/8 x 8 1/8" (25.7 x 19.7 cm). The Museum of Modern Art, New York. Gift of Richard Benson. © Light Impressions.This is the back cover of a catalog that I received the week I wrote this page. I needed something to show the pervasiveness of the computer, and I could have picked up almost any catalog that arrived in the mail (it’s close to Christmas, so there are a lot of them). This particular one is from Light Impressions, a firm that sells archival material for photographic preservation. The first thing to be said is that I was the second human being to handle this booklet. The first was the postman who put it in my mailbox, and as I took it out, I became the second. People designed it (using computers), presses printed and even bound it (also while controlled by computers), and the U.S. Postal Service delivered it to me, but nowhere in that process did a person touch any part of it. Not only has it remained pure and unsullied by the unpredictable human being but this cheap throwaway catalog, along with thousands of others, is better made than most books ever were.Web Photo Offset Print

Web photo offset print. Light Impressions Company. Light Impressions mail-order catalog, back cover. 2006. 10 1/8 x 8 1/8" (25.7 x 19.7 cm). The Museum of Modern Art, New York. Gift of Richard Benson. © Light Impressions.This is the back cover of a catalog that I received the week I wrote this page. I needed something to show the pervasiveness of the computer, and I could have picked up almost any catalog that arrived in the mail (it’s close to Christmas, so there are a lot of them). This particular one is from Light Impressions, a firm that sells archival material for photographic preservation. The first thing to be said is that I was the second human being to handle this booklet. The first was the postman who put it in my mailbox, and as I took it out, I became the second. People designed it (using computers), presses printed and even bound it (also while controlled by computers), and the U.S. Postal Service delivered it to me, but nowhere in that process did a person touch any part of it. Not only has it remained pure and unsullied by the unpredictable human being but this cheap throwaway catalog, along with thousands of others, is better made than most books ever were.Web Photo Offset Print -

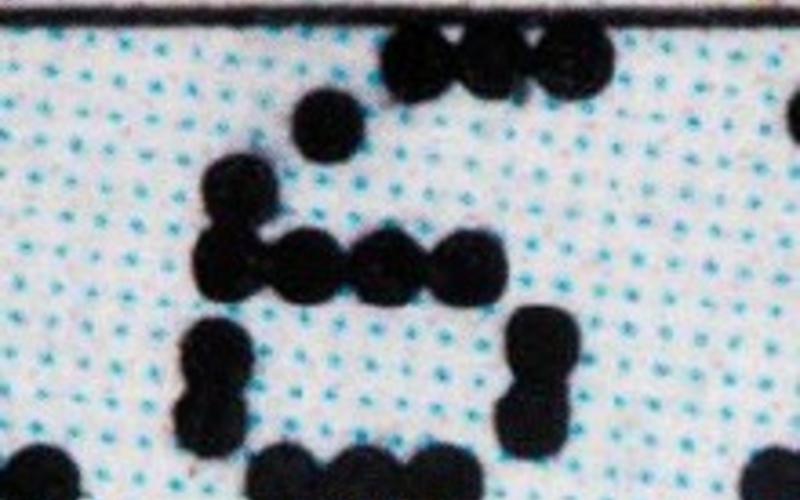

Enlargement of Web photo offset print. Light Impressions Company. Light Impressions mail-order catalog, back cover. 2006. 10 1/8 x 8 1/8" (25.7 x 19.7 cm). The Museum of Modern Art, New York. Gift of Richard Benson. © Light Impressions. Although printed at high speed on a web press, and using a halftone pattern generated by the computer, the dot pattern shown in this detail has remained the same for the seventy years or so in which process-color printing with halftones has been common.The reproductions are crisp and, when clothing or household goods are being harped, the colors are brilliant. Those of us who cling to the past should be absolutely clear that almost everything about printing is better now than it ever was before, and that this is thanks to today’s remarkable digital tools. I reproduce the back cover because it shows the small pale-yellow and pale-blue rectangles in which code numbers have been printed. Those numbers are unique, and define this catalog as the specific one that was sent to Richard Benson to help him buy stuff. The numbers link to huge databases, generated to place me in a group of likely clients for this company’s products. These databases in turn are part of an even larger, nebulous data entity comprising the aggregate of databases from many companies selling many different products.Enlargement of Web Photo Offset Print

Enlargement of Web photo offset print. Light Impressions Company. Light Impressions mail-order catalog, back cover. 2006. 10 1/8 x 8 1/8" (25.7 x 19.7 cm). The Museum of Modern Art, New York. Gift of Richard Benson. © Light Impressions. Although printed at high speed on a web press, and using a halftone pattern generated by the computer, the dot pattern shown in this detail has remained the same for the seventy years or so in which process-color printing with halftones has been common.The reproductions are crisp and, when clothing or household goods are being harped, the colors are brilliant. Those of us who cling to the past should be absolutely clear that almost everything about printing is better now than it ever was before, and that this is thanks to today’s remarkable digital tools. I reproduce the back cover because it shows the small pale-yellow and pale-blue rectangles in which code numbers have been printed. Those numbers are unique, and define this catalog as the specific one that was sent to Richard Benson to help him buy stuff. The numbers link to huge databases, generated to place me in a group of likely clients for this company’s products. These databases in turn are part of an even larger, nebulous data entity comprising the aggregate of databases from many companies selling many different products.Enlargement of Web Photo Offset Print -

Enlargement of Web photo offset print. Light Impressions Company. Light Impressions mail-order catalog, back cover. 2006. 10 1/8 x 8 1/8" (25.7 x 19.7 cm). The Museum of Modern Art, New York. Gift of Richard Benson. © Light Impressions. The information customizing the catalog for a specific recipient has been printed on top of the conventional halftone. The coarse dots have been digitally generated, and are printed in poor register, but the numbers they display have changed for every single copy in the thousands of the edition.A number of businesses, instead of selling products, instead deal only in sales data, which they market to those who still sell hard goods. We are part of this web, and even though it makes us nervous we happily take advantage of its benefits. To top it all off, the cover of the catalog has a photograph on it. The history of that picture is as follows: John Sexton made a negative and printed it; the print was scanned, plated, and printed in ink as the cover of his book; that cover was then scanned, plated, and printed on the catalog; I got the catalog, scanned it, tuned it, and sent it to the printer of my own book. Even after all this, the picture looks pretty good. The union of photography, computer, paper, and press is an absolute miracle in its present state.Enlargement of Web Photo Offset Print

Enlargement of Web photo offset print. Light Impressions Company. Light Impressions mail-order catalog, back cover. 2006. 10 1/8 x 8 1/8" (25.7 x 19.7 cm). The Museum of Modern Art, New York. Gift of Richard Benson. © Light Impressions. The information customizing the catalog for a specific recipient has been printed on top of the conventional halftone. The coarse dots have been digitally generated, and are printed in poor register, but the numbers they display have changed for every single copy in the thousands of the edition.A number of businesses, instead of selling products, instead deal only in sales data, which they market to those who still sell hard goods. We are part of this web, and even though it makes us nervous we happily take advantage of its benefits. To top it all off, the cover of the catalog has a photograph on it. The history of that picture is as follows: John Sexton made a negative and printed it; the print was scanned, plated, and printed in ink as the cover of his book; that cover was then scanned, plated, and printed on the catalog; I got the catalog, scanned it, tuned it, and sent it to the printer of my own book. Even after all this, the picture looks pretty good. The union of photography, computer, paper, and press is an absolute miracle in its present state.Enlargement of Web Photo Offset Print

Long-Edition Rotogravure (05:55 - 07:55)

-

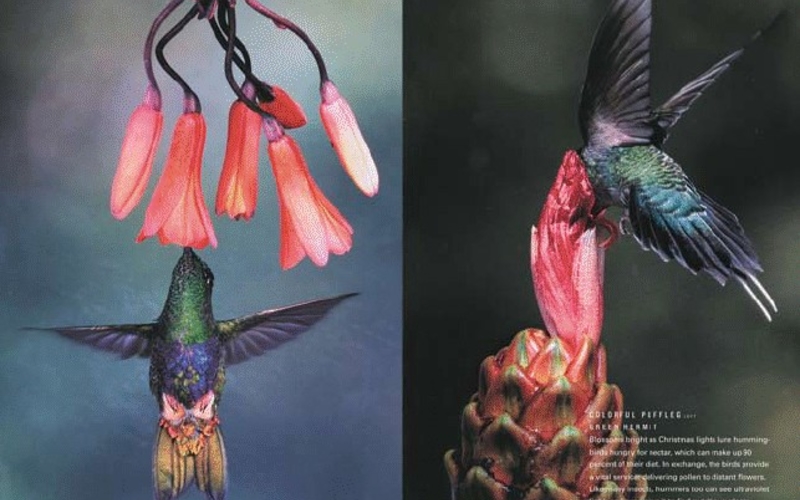

Web press rotogravure. Luis A. Mazariegos. Eriocnemis mirabilis (left) and Phaethornis guy (right) from National Geographic, January 2007. c. 2006. 10 x 13 3/4" (25.4 x 34.9 cm) each. The Museum of Modern Art, New York. Gift of Richard Benson © Luis A. MazariegosThis is a spread from National Geographic. The publishers of this venerable magazine have long been dedicated to high-quality production, and have sought to maintain this quality as the size of the print run keeps growing. The solution, surprisingly enough, has been to print in gravure, the oldest of the ink-printing systems for photography. There is gravure in its early flat-plate stage, where the inking and wiping were done by hand. Then gravure’s rotary version's screened images were etched to variable depths and printed in longer editions with mechanical inking and printing. Almost all applications of gravure died out as offset became dominant, but one remained: this is magazine work in beautiful color, printed in editions in the many hundreds of thousands.Web Press Rotogravure

Web press rotogravure. Luis A. Mazariegos. Eriocnemis mirabilis (left) and Phaethornis guy (right) from National Geographic, January 2007. c. 2006. 10 x 13 3/4" (25.4 x 34.9 cm) each. The Museum of Modern Art, New York. Gift of Richard Benson © Luis A. MazariegosThis is a spread from National Geographic. The publishers of this venerable magazine have long been dedicated to high-quality production, and have sought to maintain this quality as the size of the print run keeps growing. The solution, surprisingly enough, has been to print in gravure, the oldest of the ink-printing systems for photography. There is gravure in its early flat-plate stage, where the inking and wiping were done by hand. Then gravure’s rotary version's screened images were etched to variable depths and printed in longer editions with mechanical inking and printing. Almost all applications of gravure died out as offset became dominant, but one remained: this is magazine work in beautiful color, printed in editions in the many hundreds of thousands.Web Press Rotogravure -

Detail of Web press rotogravure. Luis A. Mazariegos. Eriocnemis mirabilis (left) and Phaethornis guy (right) from National Geographic, January 2007. c. 2006. 10 x 13 3/4" (25.4 x 34.9 cm) each. The Museum of Modern Art, New York. Gift of Richard Benson © Luis A. Mazariegos. This detail shows the soft gravure printing dots, which vary in strength as well as size. The older, rectilinear dot pattern generated by a gravure screen has given way to circular, laser-etched printing cells.The cylinders used for this kind of printing no longer carry a plate but print from copper electroplated onto a chrome cylinder. After the print run is completed, the copper is removed, a new layer of the metal is electroplated on, and the information for a new publication is etched into it. This etch is done directly, with a laser, instead of with the old carbon tissue. It might cost $2,000 to make a single cylinder, and a set of sixteen pages might require eight of these, but once they are made, the printing cylinders can print a million copies without wearing out, and do so with absolute consistency.The machines that do this are immense, often printing in multiple units so that all of the signatures are assembled into a complete publication in one operation. The terrific cost of preparatory work becomes practical when it is distributed over a huge edition. A set of cylinders might cost $100,000 for a single edition, but if a million copies are printed, that cost amounts to only a dime a copy. Gravure lives on, making beautiful pages, in the surprising niche of lush, extremely-long-edition color printing. It is a little like the steam engine. This was the prime mover that drove the industrial revolution, in stationary engines running factories and in locomotives carrying huge loads for pennies a mile. Gradually these old vapor-based machines were driven to obsolescence by the internal combustion engine, burning gasoline in cars and diesel fuel in trains. Most people don’t realize that steam still lives, hiding in huge electrical power plants, where it drives the turbines that make 90 percent of all the electricity used in the world. The heat source might come from atomic reactions, and highly advanced turbines might convert the heat to work, but the same old steam powers a large part of our society. Odd hiding places can occur where old technologies live on in new and important roles.Detail of Web Press Rotogravure

Detail of Web press rotogravure. Luis A. Mazariegos. Eriocnemis mirabilis (left) and Phaethornis guy (right) from National Geographic, January 2007. c. 2006. 10 x 13 3/4" (25.4 x 34.9 cm) each. The Museum of Modern Art, New York. Gift of Richard Benson © Luis A. Mazariegos. This detail shows the soft gravure printing dots, which vary in strength as well as size. The older, rectilinear dot pattern generated by a gravure screen has given way to circular, laser-etched printing cells.The cylinders used for this kind of printing no longer carry a plate but print from copper electroplated onto a chrome cylinder. After the print run is completed, the copper is removed, a new layer of the metal is electroplated on, and the information for a new publication is etched into it. This etch is done directly, with a laser, instead of with the old carbon tissue. It might cost $2,000 to make a single cylinder, and a set of sixteen pages might require eight of these, but once they are made, the printing cylinders can print a million copies without wearing out, and do so with absolute consistency.The machines that do this are immense, often printing in multiple units so that all of the signatures are assembled into a complete publication in one operation. The terrific cost of preparatory work becomes practical when it is distributed over a huge edition. A set of cylinders might cost $100,000 for a single edition, but if a million copies are printed, that cost amounts to only a dime a copy. Gravure lives on, making beautiful pages, in the surprising niche of lush, extremely-long-edition color printing. It is a little like the steam engine. This was the prime mover that drove the industrial revolution, in stationary engines running factories and in locomotives carrying huge loads for pennies a mile. Gradually these old vapor-based machines were driven to obsolescence by the internal combustion engine, burning gasoline in cars and diesel fuel in trains. Most people don’t realize that steam still lives, hiding in huge electrical power plants, where it drives the turbines that make 90 percent of all the electricity used in the world. The heat source might come from atomic reactions, and highly advanced turbines might convert the heat to work, but the same old steam powers a large part of our society. Odd hiding places can occur where old technologies live on in new and important roles.Detail of Web Press Rotogravure

The Indigo Printer (09:48 - 14:30)

-

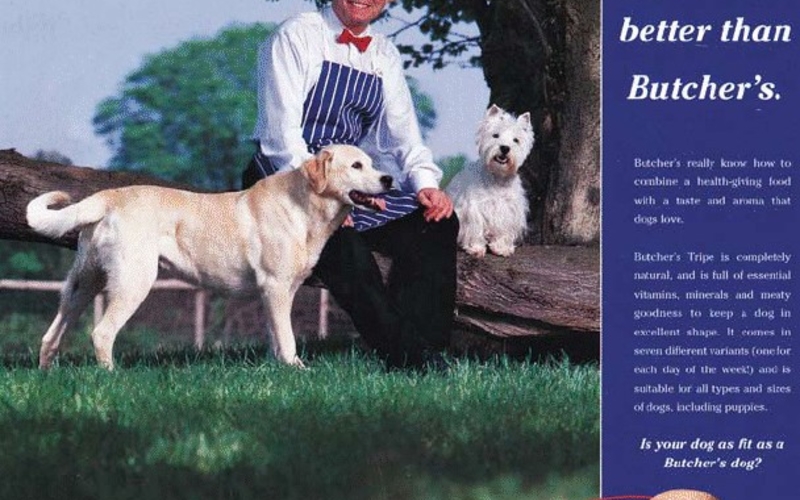

Indigo print. Impressions Digital Color. Butcher’s Tripe Range. 2006. 10 5/8 x 8 1/8" (27 x 20.7 cm). Printed by GHP (Gist/Herlin Press). 2006. The Museum of Modern Art, New York. Gift of Richard Benson. Proof for an advertisement.The computer has altered all phases of printing but one aspect of the practice has remained stable since books were first printed: the designing, printing, and binding of a book in an edition that can then be marketed. The publisher puts up the money; the paper merchant, printer, and binder all get paid, and sometimes the author even gets compensation too, but all of these funds are handed out at the publisher’s risk that the book won’t sell. The economics are shocking to many photographers who naively want to have a book of their work published, because the actual making of the book only costs about 15 percent of the retail price (and that’s for a really well-made book!). Many publishers regularly lose their shirts on books, and only stay in business because some of the titles they publish hit the big time and make up for the losses.Indigo Print

Indigo print. Impressions Digital Color. Butcher’s Tripe Range. 2006. 10 5/8 x 8 1/8" (27 x 20.7 cm). Printed by GHP (Gist/Herlin Press). 2006. The Museum of Modern Art, New York. Gift of Richard Benson. Proof for an advertisement.The computer has altered all phases of printing but one aspect of the practice has remained stable since books were first printed: the designing, printing, and binding of a book in an edition that can then be marketed. The publisher puts up the money; the paper merchant, printer, and binder all get paid, and sometimes the author even gets compensation too, but all of these funds are handed out at the publisher’s risk that the book won’t sell. The economics are shocking to many photographers who naively want to have a book of their work published, because the actual making of the book only costs about 15 percent of the retail price (and that’s for a really well-made book!). Many publishers regularly lose their shirts on books, and only stay in business because some of the titles they publish hit the big time and make up for the losses.Indigo Print -

Detail of Indigo print. Impressions Digital Color. Butcher’s Tripe Range. 2006. 10 5/8 x 8 1/8" (27 x 20.7 cm). Printed by GHP (Gist/Herlin Press). 2006. The Museum of Modern Art, New York. Gift of Richard Benson. The dot used by the Indigo printer looks identical to the dot used in conventional offset lithography.There is an old tale about a publisher who wins the lottery, and instead of retiring decides to keep publishing until the money is all gone. The stubbornly persistent practice here is that of printing the entire edition at once. This habit can be traced back to preparatory costs and the need for printing presses to be tuned and “made ready” before they can print well. That preliminary work is so expensive that it is only undertaken when a large edition is to be printed. If we print 5,000 sheets on a multicolor offset press, that work might cost about $3,000, or sixty cents a sheet. If we use the same technology to print only five sheets, the run will still cost at least $1,000, because, even though we use much less paper, the prepress work and makeready remain the same. For the small edition the cost per sheet would then be a horrifying $200.The computer might change this. One specific piece of technology that could do so is the Indigo press, which is now owned and sold (or leased) by Hewlett-Packard. This press is an offset press, still printing on a blanket from an ink-bearing plate, but the plate is electronic and can change its data set with every revolution of the press. That innovation is combined with the equally remarkable one of an ink that completely leaves the plate and blanket with each impression, so no residue remains from sheet to sheet. Rather than having to print the same page repeatedly between make-readies, the press can print the pages of a book sequentially, one after the other. This innovation permits the printing of single copies of a book at a reasonable cost. This technology, like that of the production-level color copiers, can produce books on demand. Huge inventories, storage warehouses, and publisher’s risk could all disappear if this practice became widespread. Even more important, such a development would support the making of books that are only viable for a small audience.Detail of Indigo Print

Detail of Indigo print. Impressions Digital Color. Butcher’s Tripe Range. 2006. 10 5/8 x 8 1/8" (27 x 20.7 cm). Printed by GHP (Gist/Herlin Press). 2006. The Museum of Modern Art, New York. Gift of Richard Benson. The dot used by the Indigo printer looks identical to the dot used in conventional offset lithography.There is an old tale about a publisher who wins the lottery, and instead of retiring decides to keep publishing until the money is all gone. The stubbornly persistent practice here is that of printing the entire edition at once. This habit can be traced back to preparatory costs and the need for printing presses to be tuned and “made ready” before they can print well. That preliminary work is so expensive that it is only undertaken when a large edition is to be printed. If we print 5,000 sheets on a multicolor offset press, that work might cost about $3,000, or sixty cents a sheet. If we use the same technology to print only five sheets, the run will still cost at least $1,000, because, even though we use much less paper, the prepress work and makeready remain the same. For the small edition the cost per sheet would then be a horrifying $200.The computer might change this. One specific piece of technology that could do so is the Indigo press, which is now owned and sold (or leased) by Hewlett-Packard. This press is an offset press, still printing on a blanket from an ink-bearing plate, but the plate is electronic and can change its data set with every revolution of the press. That innovation is combined with the equally remarkable one of an ink that completely leaves the plate and blanket with each impression, so no residue remains from sheet to sheet. Rather than having to print the same page repeatedly between make-readies, the press can print the pages of a book sequentially, one after the other. This innovation permits the printing of single copies of a book at a reasonable cost. This technology, like that of the production-level color copiers, can produce books on demand. Huge inventories, storage warehouses, and publisher’s risk could all disappear if this practice became widespread. Even more important, such a development would support the making of books that are only viable for a small audience.Detail of Indigo Print

Scanner as Camera (07:56 - 09:47)

-

Digital scan. Allan Chasanoff. Self-portrait. c. 1990. 1013 x 720 pixels © Allan Chasanoff.Cameras existed before photography was invented. They used a lens that projected light onto a ground glass, producing a two-dimensional image that could be traced. A pinhole can also project a dim but fairly sharp picture, and natural cameras turn up occasionally using such tiny apertures. The most common one is found in solar eclipses, when every small bit of light coming through the leaves of a tree shows the eroding crescent of the sun. Cameras have used this fundamental structure—of a point projecting a circle of definition onto a flat plane—for the entire history of photography. One of the delights of the computer age is that it has brought us a completely new kind of camera to accompany the old one in our photographic toolbox. We don’t call it a camera but a “scanner,” and it is a new and very exciting method for gathering visual data.Digital Scan

Digital scan. Allan Chasanoff. Self-portrait. c. 1990. 1013 x 720 pixels © Allan Chasanoff.Cameras existed before photography was invented. They used a lens that projected light onto a ground glass, producing a two-dimensional image that could be traced. A pinhole can also project a dim but fairly sharp picture, and natural cameras turn up occasionally using such tiny apertures. The most common one is found in solar eclipses, when every small bit of light coming through the leaves of a tree shows the eroding crescent of the sun. Cameras have used this fundamental structure—of a point projecting a circle of definition onto a flat plane—for the entire history of photography. One of the delights of the computer age is that it has brought us a completely new kind of camera to accompany the old one in our photographic toolbox. We don’t call it a camera but a “scanner,” and it is a new and very exciting method for gathering visual data.Digital Scan -

Digital scan. Allan Chasanoff. Self-portrait. c. 1990. 498 x 347 pixels © Allan Chasanoff.The scanner began as a rotary device that drew a stream of data from a rotating drum onto which a film transparency had been placed. As the drum rotated, the scanner eye moved slowly parallel to the drum’s axis and extracted a spiral thread of tonal information from the transparency. In the first scanners this information was analog, and it controlled an output light that exposed a new piece of film on another drum rotating in sync with the first. By filtering the input light, this system could produce a set of color separations. Between input and output was a set of electronic controls that could tweak the analog flow to control the density of the new film being exposed. These scanners are still around, but are digital now and very expensive. There is also a new, inexpensive, and common device called the desktop flatbed scanner. Here a series of sensors is strung along a linear bar, which passes along the object to be copied in a direction at right angles to its array of sensors.Digital Scan

Digital scan. Allan Chasanoff. Self-portrait. c. 1990. 498 x 347 pixels © Allan Chasanoff.The scanner began as a rotary device that drew a stream of data from a rotating drum onto which a film transparency had been placed. As the drum rotated, the scanner eye moved slowly parallel to the drum’s axis and extracted a spiral thread of tonal information from the transparency. In the first scanners this information was analog, and it controlled an output light that exposed a new piece of film on another drum rotating in sync with the first. By filtering the input light, this system could produce a set of color separations. Between input and output was a set of electronic controls that could tweak the analog flow to control the density of the new film being exposed. These scanners are still around, but are digital now and very expensive. There is also a new, inexpensive, and common device called the desktop flatbed scanner. Here a series of sensors is strung along a linear bar, which passes along the object to be copied in a direction at right angles to its array of sensors.Digital Scan -

Detail of Digital scan. Allan Chasanoff. Self-portrait. c. 1990. 498 x 347 pixels © Allan Chasanoff. Since the earliest years of photography, light sources have shown up in miniature reflections in the eyes of the subjects of portraits. In this case the light we see is the long one traveling with the scanner bar. Here we see the evidence of a new, lensless imaging system.In so doing the scanner records strings of data taken from an area and builds up a picture. The origins of the principle lay in the Xerox machine, which made copies of printed material by passing a drum beneath it. I remember discovering my grade school’s first Xerox—we took great pleasure in scanning unmentionable body parts when no one else was in the office. (Even then this new machine could double as a camera.) The modern desktop scanners are very refined and their sensors can even record quite far away surfaces. They act as multiple-lens cameras, making pictures with a high degree of depth of field over an extended period of time. Even more exciting, the photographs they make are not taken from a single point: the scanning bar moves and sees its subject from more than one location.Detail of Digital Scan

Detail of Digital scan. Allan Chasanoff. Self-portrait. c. 1990. 498 x 347 pixels © Allan Chasanoff. Since the earliest years of photography, light sources have shown up in miniature reflections in the eyes of the subjects of portraits. In this case the light we see is the long one traveling with the scanner bar. Here we see the evidence of a new, lensless imaging system.In so doing the scanner records strings of data taken from an area and builds up a picture. The origins of the principle lay in the Xerox machine, which made copies of printed material by passing a drum beneath it. I remember discovering my grade school’s first Xerox—we took great pleasure in scanning unmentionable body parts when no one else was in the office. (Even then this new machine could double as a camera.) The modern desktop scanners are very refined and their sensors can even record quite far away surfaces. They act as multiple-lens cameras, making pictures with a high degree of depth of field over an extended period of time. Even more exciting, the photographs they make are not taken from a single point: the scanning bar moves and sees its subject from more than one location.Detail of Digital Scan

Pictures for Machines (14:31 - 15:13)

-

Laser print. DHL. DHL Express. Bar code. 2006. 6 3/4 x 4 1/2" (17.1 x 11.4 cm). The Museum of Modern Art, New York. Gift of Richard Benson.Throughout the long history of printing, and indeed of all forms of picture-making, images were made for the use of human beings. Something radically new began to take place in commerce in the last part of the twentieth century, in the development of the humble bar code, used to control inventories, sales data, shipment-tracking information, and so on. This simple device was innovative because it became a widespread form of picture designed solely for the use of machines, not people. Machines had been looking at pictures in industry for some time; the registration system for the web press is a good example, in which an electric eye examines a register mark to fit high-speed printing. The bar code, however, moved out into society at large and reduced the activity of the hand even more—data no longer had to be typed into a cash register or written on a slip, because all this was taken care of automatically by the data transferred when a machine read the simple code on the package.Laser Print

Laser print. DHL. DHL Express. Bar code. 2006. 6 3/4 x 4 1/2" (17.1 x 11.4 cm). The Museum of Modern Art, New York. Gift of Richard Benson.Throughout the long history of printing, and indeed of all forms of picture-making, images were made for the use of human beings. Something radically new began to take place in commerce in the last part of the twentieth century, in the development of the humble bar code, used to control inventories, sales data, shipment-tracking information, and so on. This simple device was innovative because it became a widespread form of picture designed solely for the use of machines, not people. Machines had been looking at pictures in industry for some time; the registration system for the web press is a good example, in which an electric eye examines a register mark to fit high-speed printing. The bar code, however, moved out into society at large and reduced the activity of the hand even more—data no longer had to be typed into a cash register or written on a slip, because all this was taken care of automatically by the data transferred when a machine read the simple code on the package.Laser Print -

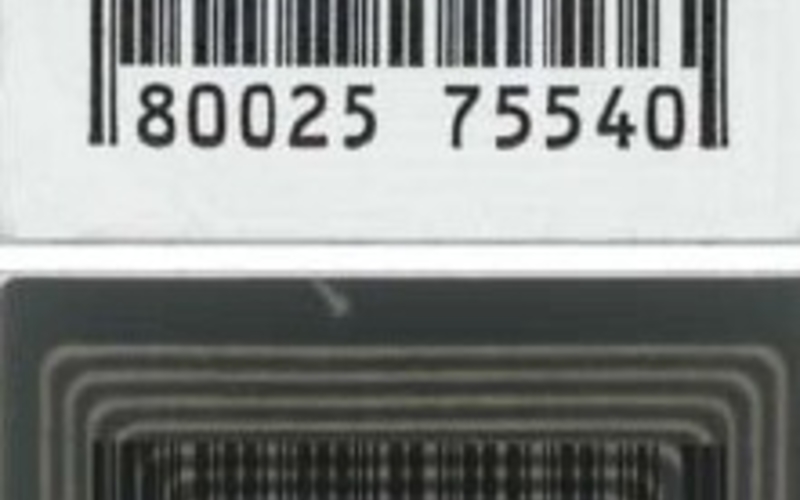

A bar code, shown at top as a reflective print and below illuminated as a transparency. This small inventory device, this one from a bookstore, contains in the dark central area a hidden picture, which, unless it is disabled during checkout, can be read electronically to alert the store that a product is being removed illegally.The bar code is read by being scanned. It is interesting that the camera used to access this information is not the old single-lens one of photography but the new one of the scanner. All forms of scanners, from the expensive ones that use a rotating drum to the cheap little ones that fit on our desk, do their work by making a picture that is not for human consumption. When we scan a picture into our computer we never see the data taken in; instead we view an analog surrogate, put up on the computer screen for our convenience. The scan itself is a string of numbers, intelligible only to the computer. It isn’t just the hand that is disappearing here but the human being as well.A Bar Code

A bar code, shown at top as a reflective print and below illuminated as a transparency. This small inventory device, this one from a bookstore, contains in the dark central area a hidden picture, which, unless it is disabled during checkout, can be read electronically to alert the store that a product is being removed illegally.The bar code is read by being scanned. It is interesting that the camera used to access this information is not the old single-lens one of photography but the new one of the scanner. All forms of scanners, from the expensive ones that use a rotating drum to the cheap little ones that fit on our desk, do their work by making a picture that is not for human consumption. When we scan a picture into our computer we never see the data taken in; instead we view an analog surrogate, put up on the computer screen for our convenience. The scan itself is a string of numbers, intelligible only to the computer. It isn’t just the hand that is disappearing here but the human being as well.A Bar Code

Conclusion (22:42 - 25:52)

-

Hand gravure. Paul Strand. Iris. 1928. 9 13/16 x 7 7/8" (25 x 20 cm). Printed by Jon Goodman and Richard Benson. 1978. Berlin. The Museum of Modern Art, New York. Gift of Richard Benson © Paul Strand Archive, Aperture Foundation, Inc.The demise of pictures in single copies is one of the first great innovations of printing, which has totally undermined the social role of pictures that exist in only one copy. Photography, even before it linked up with printing, introduced other great changes: the lens replaced the eye as a data-gathering tool and chemical processes replaced the hand in translating that data to print form. Our survey shows the steady adaptation of photography’s informational power to the printing presses, and by the end of the last century, the hand had completely disappeared from these unified visual processes. It was still in there messing around until the computer came along, but now we make and distribute multiple copies of pictures that are never touched by the ancient hand/eye/mind activity that made this little painting.The bar code gives us a warning that the hand is only the first part of the human being to disappear from picture-making. As soon as the power of pictures made for machines is recognized, the whole technological infrastructure we live in will change. As I write this, machines built to understand pictures are still crude; in concentrating on developing the technology to make pictures for people to understand, we haven’t quite realized that the technology of picture construction is just the simple, first half of the equation. The second half will be sophisticated devices to access and interpret visual data, and once those become commonplace the human being itself will start to slip out of the big picture and begin to take on a role in the background, planning and directing the show but no longer the central actor on the stage. The devices we make can already go where we are not allowed, through distances in time and space that biology simply can’t cope with, and it is just too interesting out there for this practice to do anything but grow. Before too long, technological tools will probably even comprehend what is discovered better than we can. I think we need to take on this new job and enjoy the technological child that we have been building, and that is so inevitably driving us and our biological relatives into the background. As we do so we need to recognize that some pictures, are made for the human being to enjoy, and that they should continue to be made, to exist solely for our individual pleasure.Hand Gravure

Hand gravure. Paul Strand. Iris. 1928. 9 13/16 x 7 7/8" (25 x 20 cm). Printed by Jon Goodman and Richard Benson. 1978. Berlin. The Museum of Modern Art, New York. Gift of Richard Benson © Paul Strand Archive, Aperture Foundation, Inc.The demise of pictures in single copies is one of the first great innovations of printing, which has totally undermined the social role of pictures that exist in only one copy. Photography, even before it linked up with printing, introduced other great changes: the lens replaced the eye as a data-gathering tool and chemical processes replaced the hand in translating that data to print form. Our survey shows the steady adaptation of photography’s informational power to the printing presses, and by the end of the last century, the hand had completely disappeared from these unified visual processes. It was still in there messing around until the computer came along, but now we make and distribute multiple copies of pictures that are never touched by the ancient hand/eye/mind activity that made this little painting.The bar code gives us a warning that the hand is only the first part of the human being to disappear from picture-making. As soon as the power of pictures made for machines is recognized, the whole technological infrastructure we live in will change. As I write this, machines built to understand pictures are still crude; in concentrating on developing the technology to make pictures for people to understand, we haven’t quite realized that the technology of picture construction is just the simple, first half of the equation. The second half will be sophisticated devices to access and interpret visual data, and once those become commonplace the human being itself will start to slip out of the big picture and begin to take on a role in the background, planning and directing the show but no longer the central actor on the stage. The devices we make can already go where we are not allowed, through distances in time and space that biology simply can’t cope with, and it is just too interesting out there for this practice to do anything but grow. Before too long, technological tools will probably even comprehend what is discovered better than we can. I think we need to take on this new job and enjoy the technological child that we have been building, and that is so inevitably driving us and our biological relatives into the background. As we do so we need to recognize that some pictures, are made for the human being to enjoy, and that they should continue to be made, to exist solely for our individual pleasure.Hand Gravure